Air-cooled Unit Cooler

Keywords:

Air-cooled Unit Cooler

Detailed Introduction

- Principle and product type of the air-cooled condenser:

The high temperature and high pressure gaseous refrigerant from the compressor enters the air-cooled condenser pipe, and transfers the heat to the external heat sink through the metal pipe wall with good heat conduction. Under the action of the fan, the air constantly blows through the heat sink and takes away the heat, which reduces the temperature of the refrigerant. When the condensation temperature drops, the gaseous refrigerant condensates into liquid, and the liquid refrigerant flows out from the outlet to the throttling device. After the throttling, it becomes low-temperature liquid refrigerant and enters the evaporator to complete the refrigeration cycle.

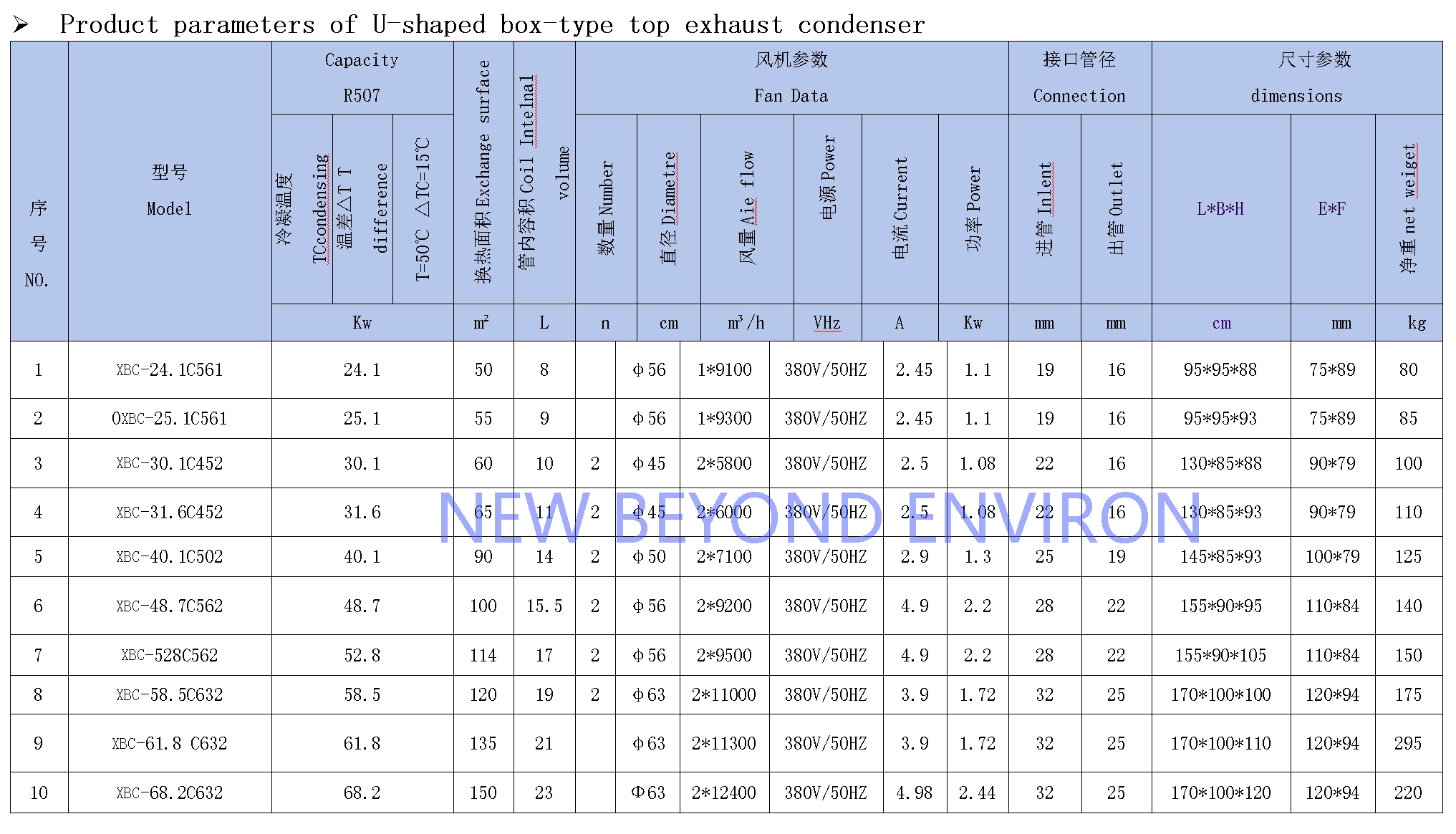

According to the appearance style of the air-cooled condenser, it can be divided into side wind, V, U, flat top wind, inclined wind, etc., and the refrigeration compression parts can be integrated into the box into an all-in-one machine.

- Advantages of air-cooled condenser:

1. Use air as a cooling medium to save water resources, reduce sewage discharge and protect the environment;

2. Flexible and simple installation, just install the product in a well-ventilated place and connect the refrigeration system pipeline and power supply; no complicated waterway system;

3. Low operation cost, and the heat dissipation capacity can be accurately adjusted by adjusting the fan speed;

4. Maintenance cost and difficulty are low, there is no scale, water leakage and other problems, only need to regularly clean the heat sink and check the motor; the maintenance cost is only 20%~30% of the water cooling system;

5. After the power supply of the fan is cut off, there is still 30%~40% of the natural cooling capacity;

- Product advantages and design concept:

1. High quality supply chain and quality requirements; coil fin material with corrosion resistance and protection treatment;

2. Diversified coil coil materials: copper pipe, stainless steel pipe, aluminum pipe, etc.;

3. A variety of high-quality sheet metal materials: stainless steel plate, aluminum plate, etc.;

4. Advanced plate processing equipment and technical talents;

5. Diversified material and appearance selection requirements.

6. High standardized procurement technical standards;

7. Non-standard customization according to requirements; provide optimal design scheme for different usage scenarios;

Previous Article

Next Article

Previous Article

Next Article

Get a Free Quote

Please leave your contact information and requirements and we will arrange for a staff member to contact you.

Series of Products