Screw refrigeration unit

Keywords:

Semi-hermetic Two-stage Screw Parallel Refrigeration Compressor U

Detailed Introduction

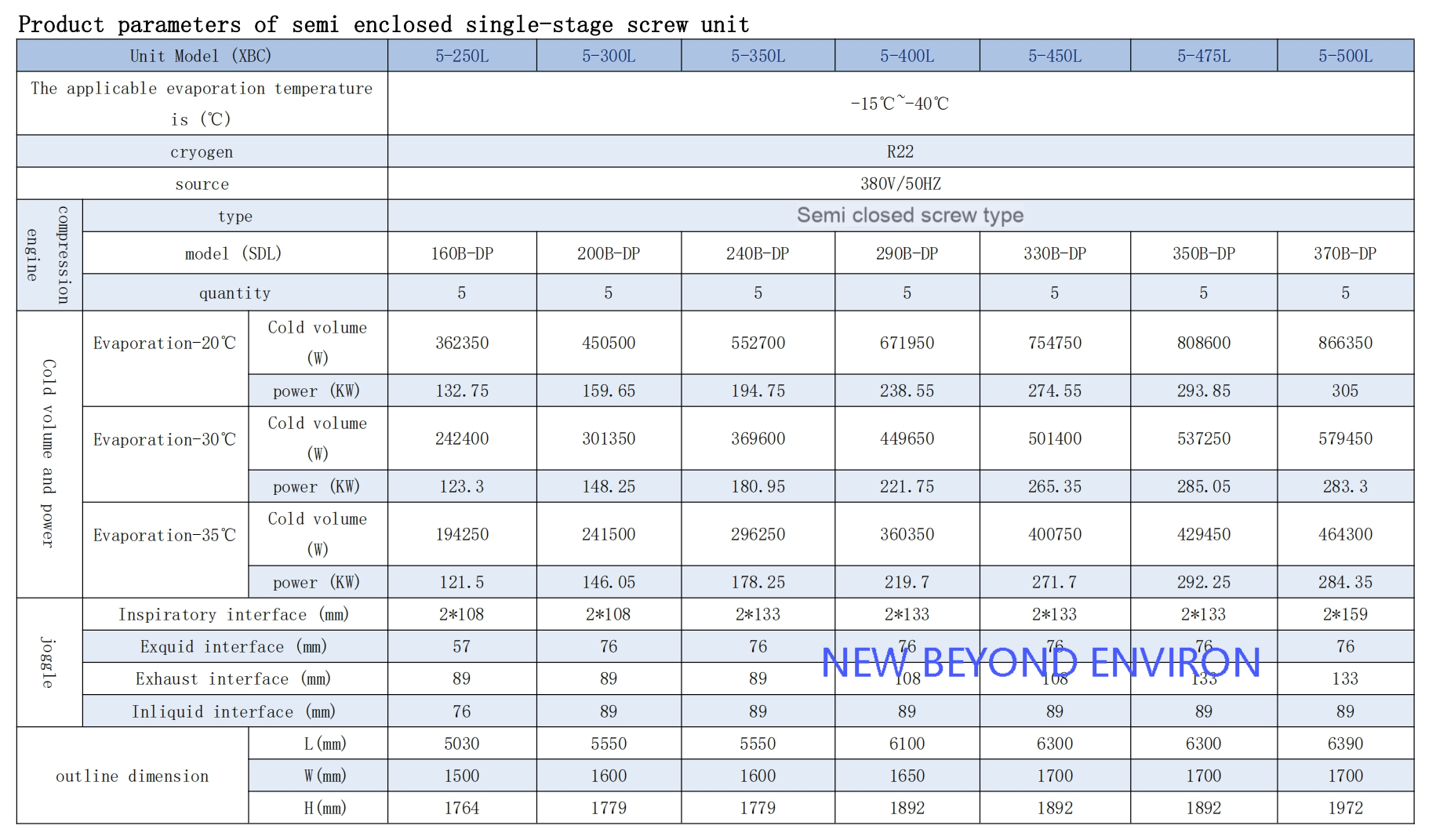

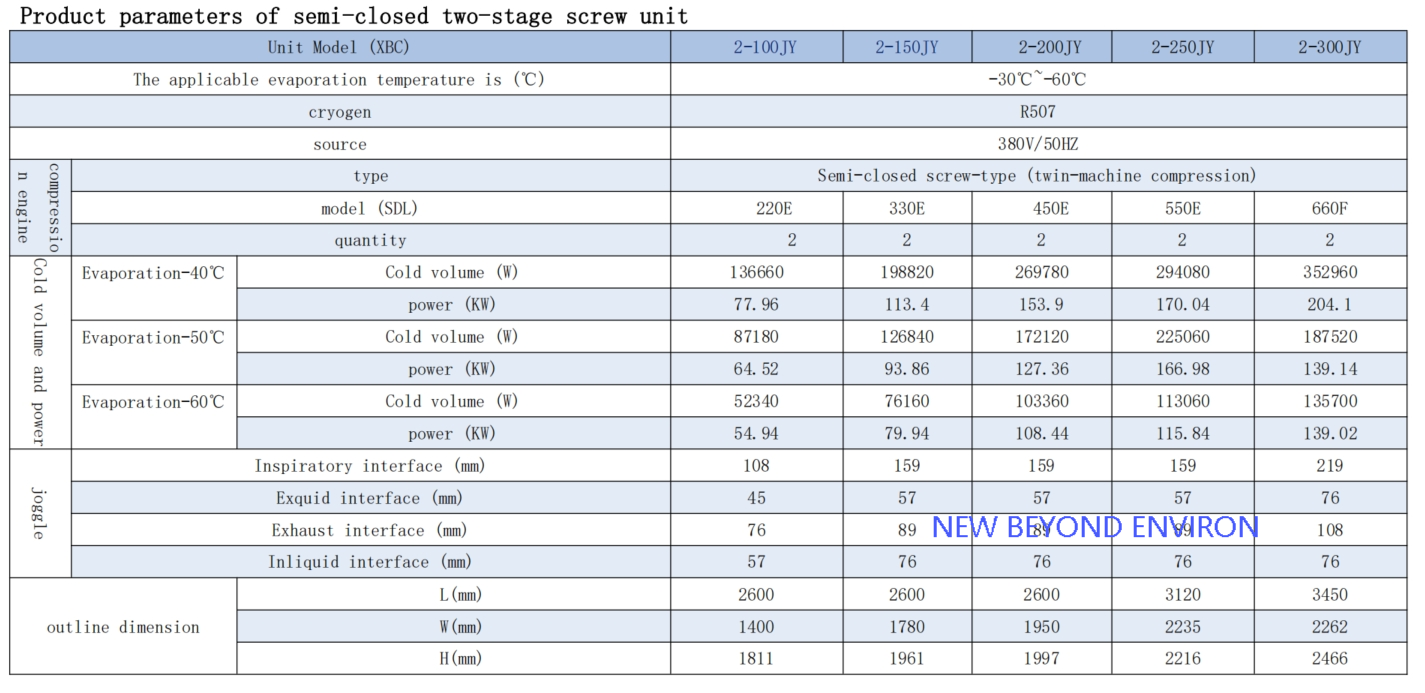

- Principle and product type of parallel screw unit:

Parallel screw unit refers to two or more compressors in parallel with a set of refrigeration circuit;

According to the different refrigeration temperature and refrigeration capacity, the formation of parallel screw unit can be varied, can be divided into high temperature and low temperature screw parallel, single-stage, two-stage screw parallel, multi-suction false parallel, etc.

- Advantages of the parallel-connected screw unit:

1. The average efficiency of a parallel unit is 30% higher than that of a single unit;

2. Multistage energy adjustment, and the cooling output of the unit can match the actual demand; multiple compressors can vary in size to match the actual load with smoother dynamic stability;

3. The controller adjusts the number of starting units according to the return gas pressure, and the unit can also maintain the highest efficiency under some loads of the unit.

4. Careful pipeline design to minimize the pipeline pressure loss to maximize the unit efficiency.

5. Compressor, oil separator, liquid supply main pipe and electronic control equipment are all concentrated together. After ensuring enough operation space, the equipment should occupy the space as far as possible and fully save the area of the machine room.

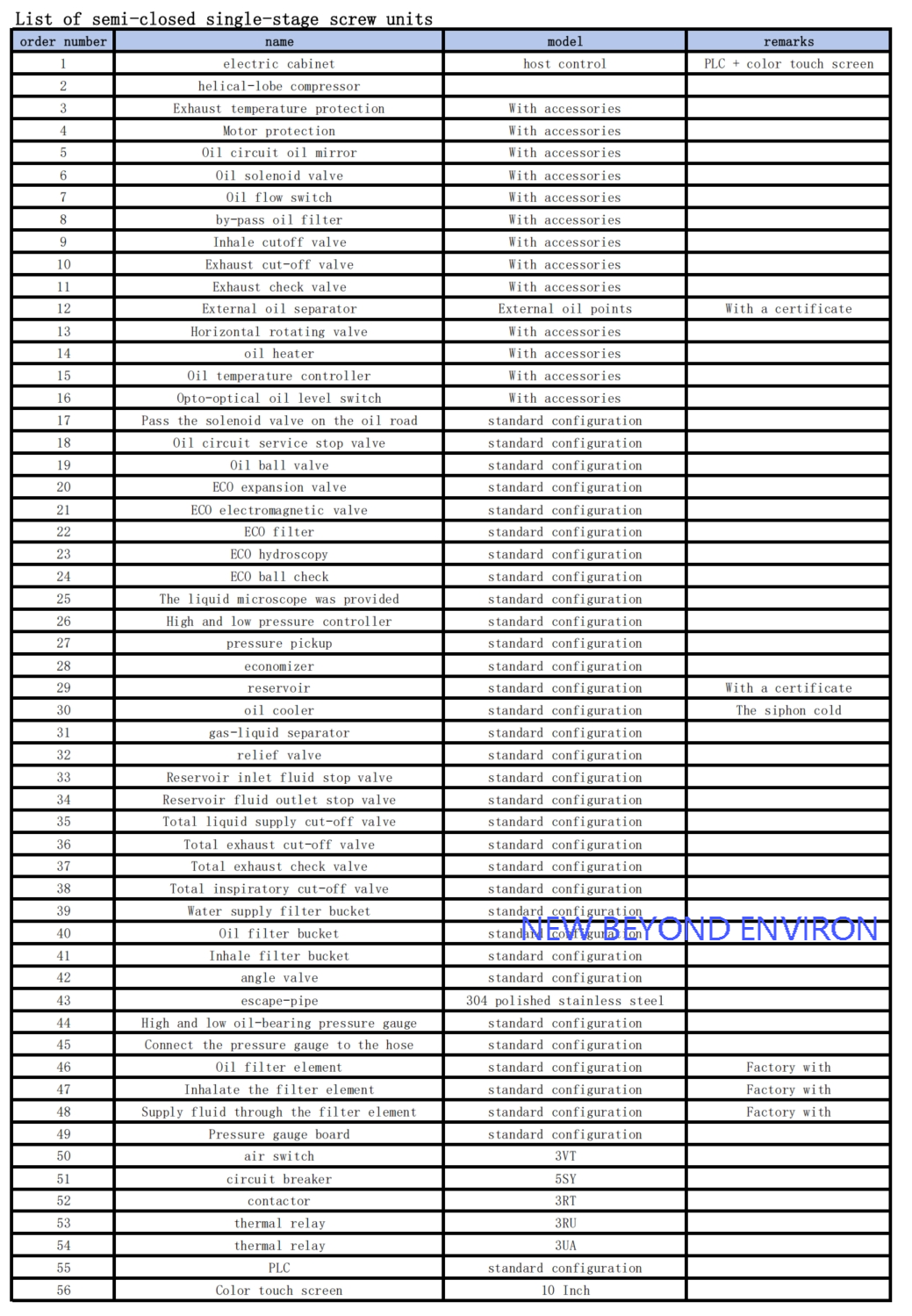

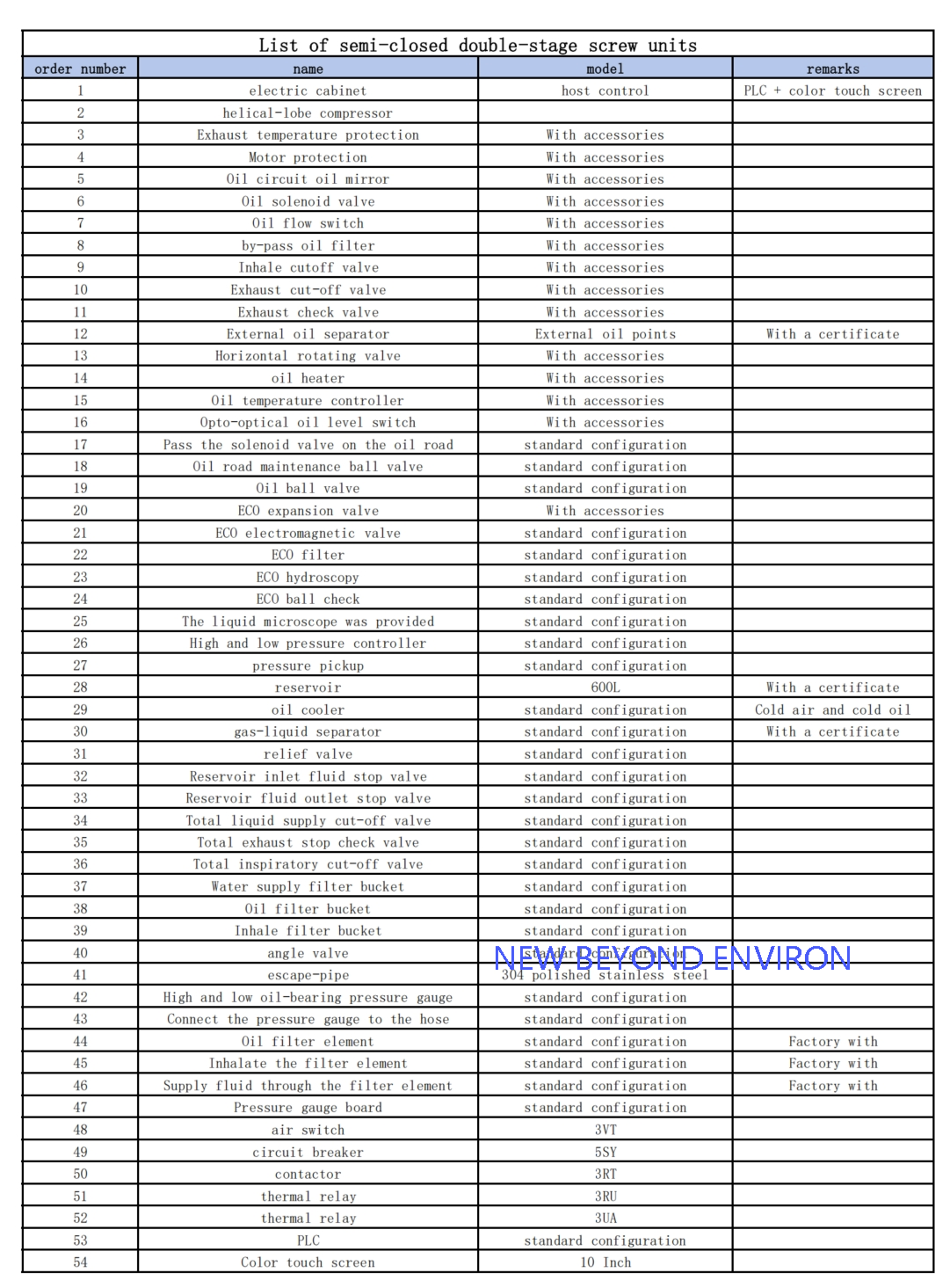

6. The parallel unit is controlled by PLC. Daily maintenance only requires one person to check the operating parameters of each equipment regularly. At the same time, due to the high operation stability of the equipment, there is no need to keep various parts, which greatly saves the equipment maintenance and labor costs.

7. Highly integrated design concept, reduce the consumption of pipelines and cables, and shorten the construction cycle.

8. There are a variety of boot modes: normal mode, power peak, flat and valley mode. According to the peak and valley time given by the local state grid. To set the compressor operating mode. For example, in the electricity valley, as long as the temperature of the warehouse is not lower than the set ultra-low temperature, the warehouse is always supplying liquid, and the compressor works at full load. For example, at the peak of electricity consumption, as long as the warehouse temperature can not reach the ultra-high temperature, the warehouse will not be opened, and the compressor works as little as possible. These are all done automatically by the PLC.

- Product advantages and design concept:

1. Compressor and control valve parts adopt high quality brand, high safety;

2. Fully consider the ergonomic design principles, reasonable spatial layout, convenient adjustment and replacement;

3. Fully consider that the system can work normally when local faults, and each branch can be truncated from the system;

4. Automatic control to minimize human factors to ensure the efficient operation of the system;

5. Non-standard customization according to requirements; provide optimal design scheme for different usage scenarios;

Previous Article

Previous Article

Get a Free Quote

Please leave your contact information and requirements and we will arrange for a staff member to contact you.

Series of Products